RhinoNC Features

RHINONC

CAM software solution integrated into Rhinoceros

Check out some of the key features of RhinoNC CAM software.

What are the key steps that enable the initial creation of high-quality, high-precision machining operations?

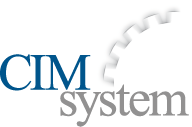

• Automatic recovery of residual material

• Recognition of unmachined areas due to the size of the tool used

• Automatic association of technological parameters

RhinoNC supports you with automated operations like those mentioned above, to better manage your machining and guarantee reliable and repeatable processes.

Tools parameters setting

Strategy parameters

RhinoNC may perform the automatic recognition of the dimension for any type of geometry whether they are curves, surfaces, solids or just meshes.

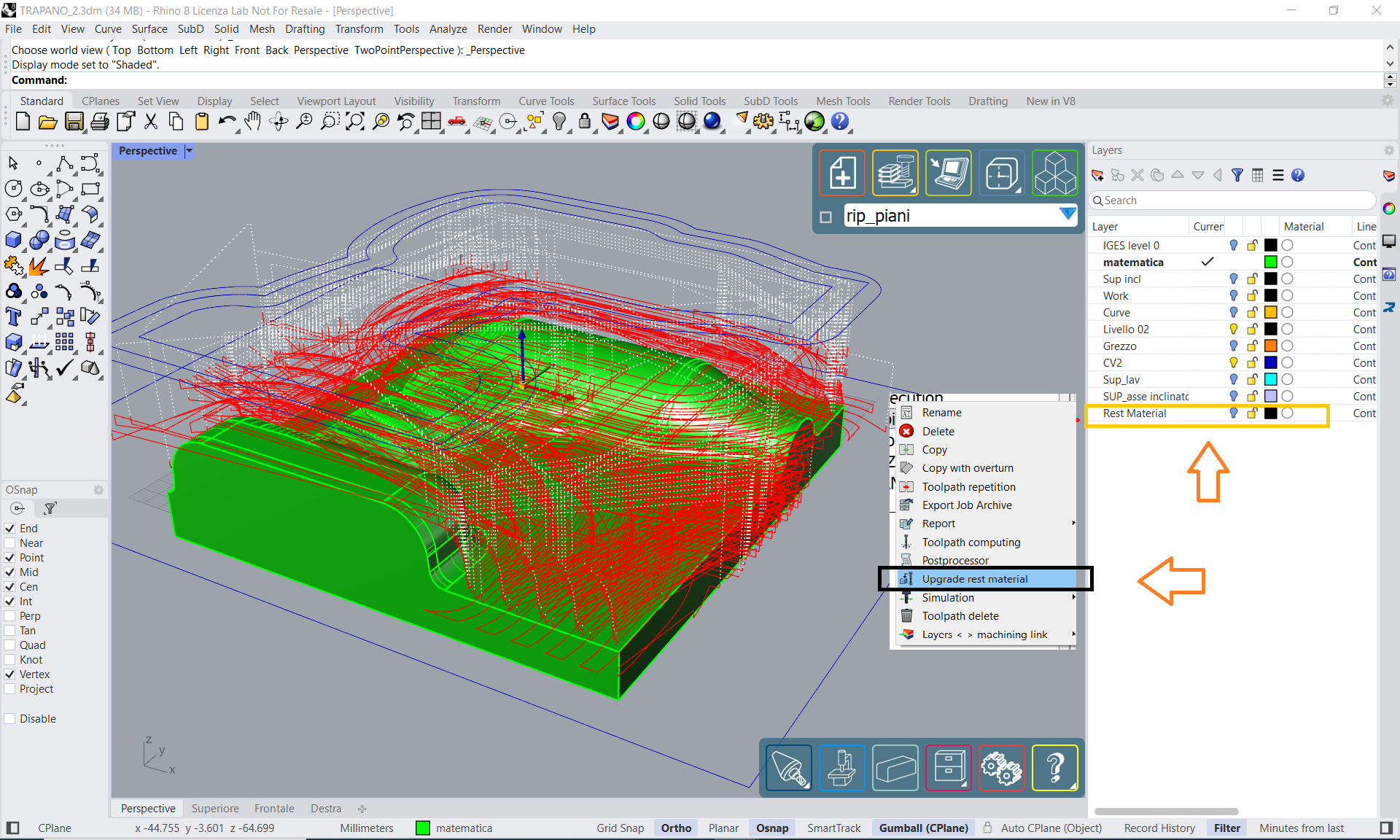

There are two possible simulations: wireframe and cinematic. Wireframe simulation: allows you to verify the toolpath machining plane by plane, point by point and get information about the piece quote. Cinematic simulation: allows you to perform collision control and verify if and how much the piece quote has changed in final product.

You can automatically generate job reports and reports about machining time to archive for your future planning. Indeed, thanks to these features, you will be able to quantify real operational time and forecast your costs.

RhinoNC comes with a series of standard postprocessors but it is also possible to request for customized postprocessors according to your machining needs.