How to choose your CAM software for CNC machine programming

CAM software is a powerful ally for the manufacturing industry. The term CAM (Computer Aided Manufacturing) refers to a category of IT products that, starting from the analysis of the 2D or 3D geometry model, generate precise tool paths to machine a finished product. This technology was born in the 1960s and represented an extremely significant turning point in industrial production by making it possible to automate and stabilize the production of mass-produced parts, minimizing human errors and speeding up processes.

The use of a CAM is strictly subordinated to the usage of a CAD design software where the initial project is created. Both systems are equally applicable to the manufacturing in a wide range of sectors such as: moulds, automotive, jewelry, manufacturing of marble, wood, or sheet metal. Computer-aided production is applicable for a variety of machining types including: milling, turning, drilling, engraving, electroerosion, and more.

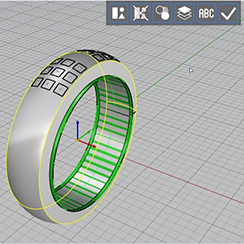

One of the most significant advantages given by the usage of CAD CAM technology is the ability to simulate the result of a manufactured product prior to machining. This crucial step allows the user to easily double-check and prevent potential errors, improving product quality and reliability. Preventive simulation involves multiple parts of the production process, including: realistic machine movement visualization, tool path representation and calculation time, collision control, residual material, and material deposit checking. As technology continues to advance, the integration of artificial intelligence (AI) and machine learning in CNC and CAM software is available to revolutionize manufacturing.

Nowadays there are many CAMs available on the market, for any kind of product machining and budget, but only a few of them are versatile and can be adapted to the needs of your evolving business.

Let’s dive into 5 tips to consider when choosing CAM software for CNC machine programming to make the difference in your actual machining.

Compatibility with existing technology:

The synergy between CAD software, CAM software, and CNC machines is a game-changer for manufacturers seeking to enhance productivity and maintain high-quality standards. The real-time communication between the software and machine ensures that any design changes or optimizations are quickly reflected. This dynamic responsiveness minimizes downtime, reduces material waste, and contributes to the overall efficiency of the manufacturing process.

To get the maximum from your CAM software, it must fit with your current machines and be able to perform multiple machining. In addition, make sure it is compatible with all the file formats required by your machines while generating easy to run tool paths. Are you currently working on 2 or 3 axis only? That’s fine, but we suggest you buy a flexible CAM that can be easily improved to perform 4 and 5 axis machining and support you regardless of changed business plans. This can save you time and money, as you already know how to use the tool.

CAM system ease of use:

The synergy between CAD software, CAM software, and CNC machines is a game-changer for manufacturers seeking to enhance productivity and maintain high-quality standards. The real-time communication between the software and machine ensures that any design changes or optimizations are quickly reflected. This dynamic responsiveness minimizes downtime, reduces material waste, and contributes to the overall efficiency of the manufacturing process.

To get the maximum from your CAM software, it must fit with your current machines and be able to perform multiple machining. In addition, make sure it is compatible with all the file formats required by your machines while generating easy to run tool paths. Are you currently working on 2 or 3 axis only? That’s fine, but we suggest you buy a flexible CAM that can be easily improved to perform 4 and 5 axis machining and support you regardless of changed business plans. This can save you time and money, as you already know how to use the tool.

Advanced set of features:

Evaluate the advanced features offered by the CNC programming software. These can include: optimized milling strategies, intelligent tool management, accurate simulation and tool path optimization functions. Advanced software can help improve production accuracy and speed.

Moreover, post-processing is the bridge between CAM software and your CNC machines. Ensure that the CAM software supports the specific post-processors required for your machines. Having the ability to customize or modify post-processors is also beneficial, allowing you to adapt the software to the unique requirements of your machining equipment.

System integration:

Make sure your CAM solution can integrate seamlessly with other business systems, such as computer-aided design (CAD) software and manufacturing management tools. Having good integration between these systems helps to eliminate data duplication and improve the overall consistency and efficiency of processes. Furthermore, it allows you to pursue the digitalization process of the company, ensuring the preservation of information. Before making a final decision, it is advisable to test the CAM software under consideration on pilot projects or request in-depth demos to fully evaluate its functionality and its adaptability to the specific needs of your company.

Technical support:

Before purchasing a CAM software, we suggest you also get some information even on the provider’s reliability. Choose a vendor that offers good technical support and fast assistance. From experience, we know well that the interruption of production represents a significant difficulty, therefore, it is essential to be able to rely on a proactive supplier, able to assist as soon as possible. Furthermore, the manufacturing industry is constantly evolving and having a software that receives regular updates is an essential way to stay up to date with latest the technologies and improvements.

RhinoNC is a CAM software available in the market for over 10 years. The power of RhinoNC is in its integration with Rhinoceros CAD software, which ensures a smooth transition from project design to machining. RhinoNC is structured into machining modules, which means that you can customize software application according to your individual needs. Lastly, RhinoNC is built side by side with its users and has the advantage of multiple recurring improvements that keep it incredibly competitive in the market.