CAD/CAM software solutions in the footwear manufacturing industry

The use of CAM software for CNC machines plays an essential role in footwear manufacturing. The process automation, introduced in the shoe industry in 1970s, provides the opportunity to quickly create repeatable pieces that perfectly replicate even the most complex design details. Moreover, the use of digital technology allows manufacturers to save material and minimize waste, thanks to well programmed toolpaths and preventive simulation. From pattern engraving on leather goods to the creation of customized soles, CAM software is applicable at every step of the footwear production process and enables you to get as close as possible to replicating the shoe design provided by the CAD system.

Furthermore, CAD/CAM solutions are able to respond to growing requests for product customization. Each pair of shoes can be adapted to the specific needs of each customer, from the choice of materials to unique designs, without consuming too much of the manufacturers time. This digitally innovated way to manufacture shoes and components opened new business opportunities for footwear manufacturers, allowing them to meet the needs of an increasingly diverse market.

Footwear manufacturing Company type and production process

Companies that work in the footwear industry can either handle the entire footwear design and production process or they can specialize in only some of its phases, such as:

- Sole and leather cutting

- Printed or prototyping object trimming. This often happens when the production is a limited series.

- Creation of molds for high production or particular models.

- Design and production of ad hoc orthopedic footwear

- Heels making

Tools, techniques and machines used by software for footwear manufacturing

Depending on the type of production required, different machines are used. For soles or leather/fabric cutting, 3-axis Cartesian machines are predominantly applied. The 2d patterns are defined by not-rotating knives, which just go smoothly along the toolpath. Therefore, the machine spindle becomes a rotary axis to be controlled by the instructions provided by the CAM to the CNC machine. In the case of mold construction, trimming, and heels making, 3 to 5 axis machines are used effectively.

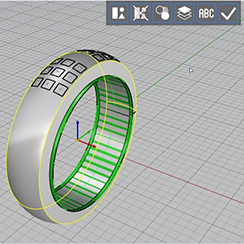

The highest performing modules utilized to increase quality and productivity in the shoe industry are the milling curve, the surface milling, and the 5-axis milling module.

There are several diverse techniques used in footwear manufacturing. They depend mainly on the type of footwear required, the materials used, and the production phase a manufacturer is working on. In detail:

- Laser Cutting: used to cut materials such as leather and fabrics precisely and quickly.

- Water jet cutting: Suitable for thicker and more diverse materials.

- 3- and 5-axis milling: used to create shapes and patterns on soles and other shoes components, even the complex ones.

- Turning: Used to work specific shoes components such as heels and other details.

- Marking and Engraving: Used to engrave or mark details and logos on materials.

- Injection molding: For the production of plastic or rubberized parts used in footwear.

- 3D Printing: To create custom soles or rapid prototypes.

- Automatic Control and check Systems.

Simplification and automation

CAM software simplifies the complexity of manufacturing processes. Thanks to advanced automation, machine tools can perform a streamlined workflow, reducing manual operations and reproducing exact specifications from the CAD system. This allows workers to focus on more creative and high-value-added activities rather than performing automated routine procedures. Furthermore, the CAM software interface is designed to facilitate the definition of all the necessary parameters to minimize the learning curve and save time.

Before purchasing a Computer-aided manufacturing software, it is necessary to verify some of the key performing parameters such as the flexibility in generating cutting paths, the range of advanced functions available, and the system integration capabilities. When looking at options you should consider:

- The automatic extraction of the curves to be machined form the 2d and 3d design;

- Automatic positioning of segments for tool orientation;

- The use of pre-configured templates in case the mold or heel needs to be created in different sizes of the shoes;

- Preventive simulation

The introduction of CAD/CAM solutions for CNC machines represents a milestone in shoe design and manufacturing. The software helps to obtain results in a short timeframe, bringing significant advantages in terms of precision, efficiency, and customization. Companies that adopt this technology are uniquely positioned to respond to evolving market needs and thrive in an increasingly competitive industry.

With RhinoNC CAM software you can generate toolpaths for every phase and every component of footwear production, running multiple high-speed machines at the same time. Furthermore, it is possible to associate RhinoNC to SHOT Plugin, integrated into Rhinoceros, which allows easy creation and management of sole or footwear scaling.