CAM software for jewelry CNC machining: process and benefits

The jewelry manufacturing industry brings together goldsmith companies and workshops to create artifacts made of metallic or mineral materials through various artisanal or industrial production processes. Jewelry creation involves various phases on the path from design to actual production. For designing, it is essential to use CAD CAM solutions that simplify production management.

Here’s an overview of main phases of jewelry production:

1. Design:

Design can be done by hand (sketch on paper, clay modelling, etc.) or digitally using Computer-Aided Design systems, which allows the operator to create more detailed artistic products.

2. 3D Modelling:

If the design was done manually, the next step is to create a three-dimensional model using a 3D scanner or digital modelling. If you used a CAD software, the 3D model will be a available immediately.

3. Prototyping:

When designing a new model or complex product it is possible to create a physical prototype using 3D printing techniques or by manually manufacturing a wax prototype.

4. Processing:

The 3D model or wax prototype is used to create a mold. Through wax casting, material (such as gold, silver, or another metal) is melted and poured into the mould to create the desired shape. Once the piece has been extracted from the mould, it is time to proceed with the actual manufacturing. This step may include finishing, polishing, adding gemstones, and any other decorative details.

5. Assembly:

During this phase precious stones or movable elements are added to the final product.

6. Final finishing:

The last step involves the final cleaning and finishing of the jewelry piece. This may include additional polishing work and final checking for any small details or imperfections. After the finishing phase, the product is ready to be packaged and prepared for distribution or sale.

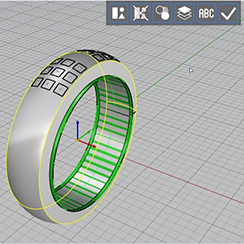

Jewlery design and manufacturing requires the use of multiple machining modules and specific tools that are different when compared to standard milling tools. Circular grinding wheels or abrasive tools are used, especially to work minerals and polish metal objects, while cone and burin tools are used to provide a nice finish to engraved details. Machining and toolpath creation operations, are performed by using all milling modules available for CNC machines from 2.5 to 5-axis machining depending on the product geometry, complexity and shape, 2.5-axis curved processing modules with conical tools are mainly used in engraving to create writing, logos or articulated designs, while 4 and 5-axis milling module are preferred when crafting rings, or bracelets or decorative objects.

The benefits of using a CNC software for jewelry design on CNC milling machines

Flexibility: CAM systems can be configured to work with a wide range of materials, from plastics to precious metals. This allows jewelers to experiment with different materials to create unique pieces.

Waste reduction: Efficient use of materials is often an advantage provided by using digital solutions. Digital solutions can be programmed to optimize the cutting and processing of materials, reducing overall material waste.

Innovation in Design: CAD design combined with CNC software usage allows manufacturers to experiment with a huge variety of innovative designs that may be difficult to create manually. This paves the way for new ideas and concepts in the jewelry industry.

Adaptation: The ability to quickly adapt to new designs or changes in market demands are key advantages of using digital technology. The flexibility given by innovative solutions allows operators to easily modify production processes in response to market needs.

Integration: The integration between Computer-Aided Design and Computer-Aided Manufacturing enables a seamless workflow from concept to production. This facilitates the transformation of the designer ‘s idea into a finished product.

One current solution known worldwide for its use in the industry is Rhinoceros, a cutting-edge 3D CAD. Rhinoceros is a CAD filled with advanced features and supports a multitude of rendering plug-ins, to eliminate the cost of one single piece creation of unique check before production.

Rhino NC, a software developed and sold by CIMsystem, is an easy-to-use solution that offers a set of specific functions for jewelry piece production. These functions simplify the process and are available regardless of the material and milling machine used. Rhino NC also helps you to efficiently make custom changes to your strategies, addressing and solving individual user needs. Integrated directly into Rhinoceros, RhinoNC software offers a seamless and optimized user experience that is pushing past the limits of traditional jewelry manufacturing.