Pyramis Features

PYRAMIS

Dental 3D printing software

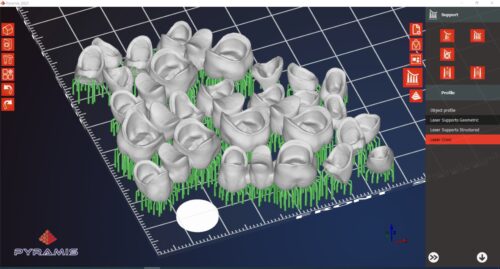

Lots of automated functions, innovative operations and the posibility of integrating the 3D printing technique with milling technologies at low effort turn Pyramis into a 3D printing software you will never be apart from.

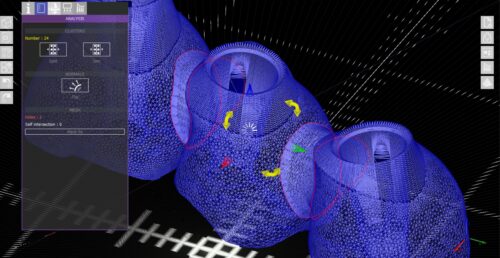

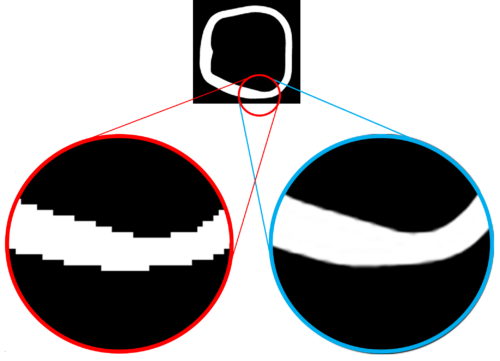

The file is analyzed during the import process to detects any intersections, holes or anomalies and to make a preliminary evaluation of project quality. Moreover, thanks to a powerful mesh fixer, is possible to detect any mesh issue and fix with a single click, making the mesh quickly ready for the printing process.

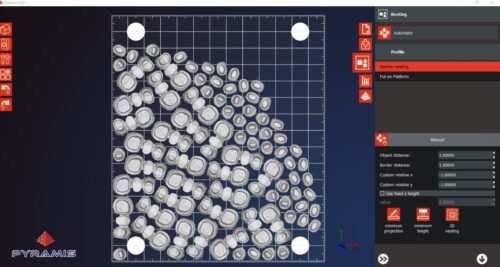

The automatic nesting is one of the Pyramis Features that help customers the most. A powerful 2D nesting algorithm allows to fill the plate with objects in a short time, giving also information about the distance between the objects themselves and the edge and keeping it constant. This function also allows you to select the area of the plate on which to start the automatic placement process.