Make&Mill News

MAKE&MILL

Dental CAM for milling and 3D printing

Make&Mill News.

2024

CALIBRATION

2023

TOUCH PROBE

2021

OVERLAY CHECK

2020

OFFSET MESH

2024

CALIBRATOR

Make&Mill precision performance can be further enhanced through the use of a calibration tool. Using this tool, the operator can check the machine calibration at any time. The hardware is not included with software purchase but needs to be purchased separately.

2023

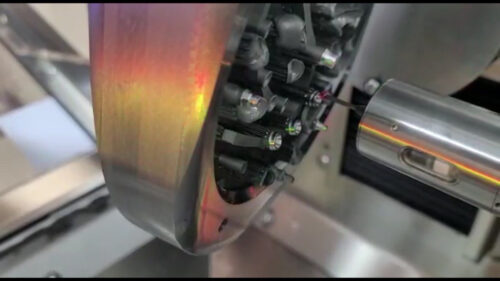

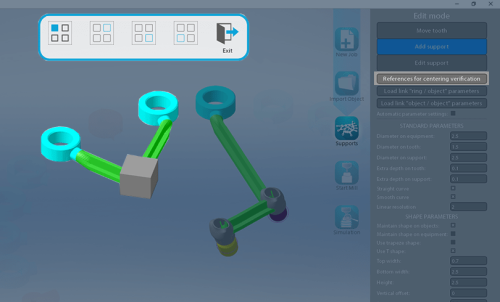

TOUCH PROBE

Make&Mill is known for producing high quality results on refined restorations. However, through use of a touch probe it is possible to be even more accurate concerning workpiece quality.

The touch probe allows the piece to be centered in the machine, verifying the positioning of specific reference points. Measurement and dimensional verification operations are performed to compare the final result with the initial project.

2021

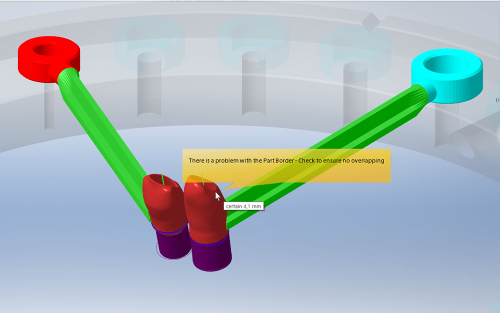

OVERLAY CHECK

Thanks to this function, Make&Mill can send you an alert in cases of extreme object proximity. This feature allows you to better project your project from damage and have more confidence about the final result.

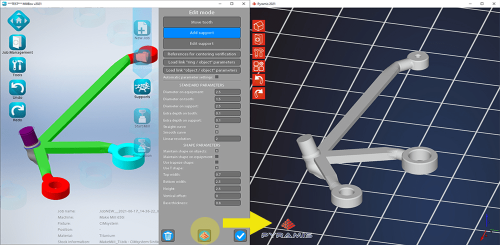

3D PRINTING SOFTWARE INTEGRATION

Make&Mill integrates seamlessly with our 3D printing software Pyramis. Execute the entire workflow and switch between the two different software interfaces with just a single click.

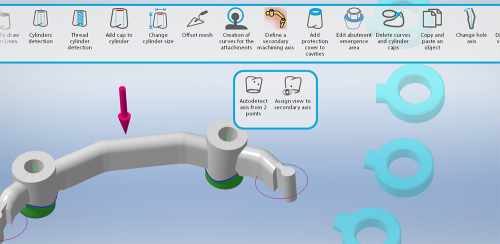

DETECTION OF SECONDARY AXIS

With this function you can better refine complex objects and simultaneously reduce manual operations. Save time on your operations and reduce the risk of manual operator error.

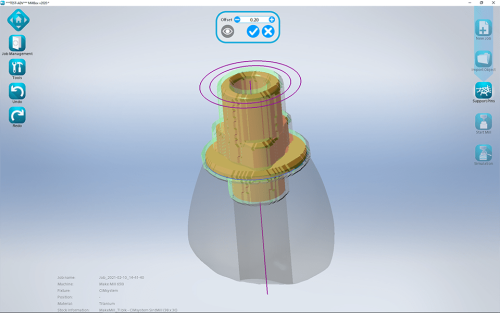

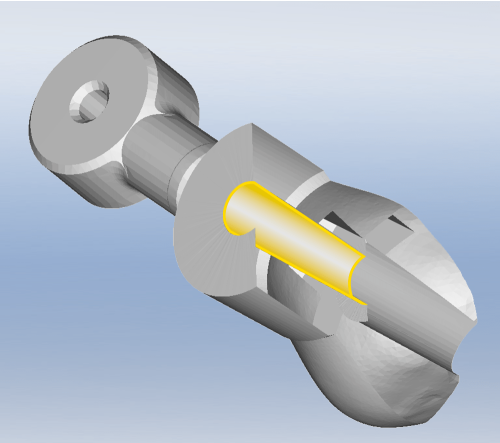

ADD A PROTECTIVE COVER TO AN EXISTING INTERFACE

Make&Mill optimizes tool consumption by adding shaped protective covers with radial offsets to pieces with interfaces

2020

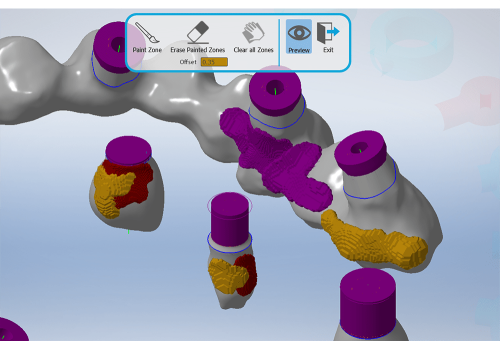

OFFSET MESH

Make&Mill allows you to select only the areas you need to modify by adding material. This can be an essential function in case of calibration errors on printing machines or to refine the object to get a better product at no effort.

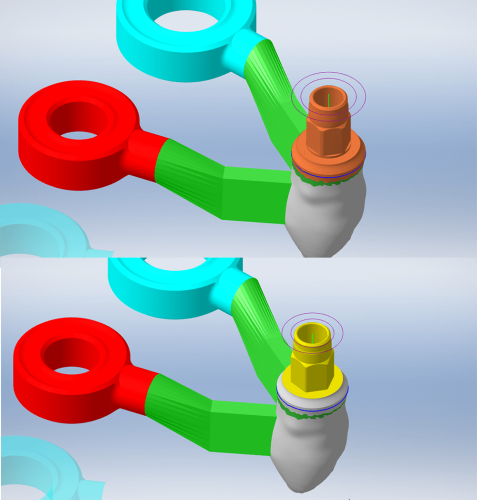

REPLACE FUNCTION

Now the replace function in M&M can be executed even if the object is linked to the connectors. You can now you replace what you need whenever you need, regardless the project status. Execute the replace function while keeping the connectors also gives you the certainty of keeping the object in the same position.

PROTECTIVE CUPS WITH SCREW HOLE

The function of applying protective caps with screw hole gives you the possibility of reducing tool consumption and calculation time. Moreover, thanks to this function enhancement you could also handle even cases where none of the connections have a screw hole.

MULTIPLE INTERFACES PROTECTION

Make&Mill is now able to select multiple connections at the same time to apply the same type of protection, this allows you to save time in getting the final result.