The development of fixed prosthesis solutions is an important step in implantology, providing patients with improved stability and aesthetics. Recent scientific research has given an important boost to the development of fixed dental devices, with leading projects like the OT Bridge protocol emerging. This method was created using a combination of innovative components that stabilize the prosthesis effectively, while also reducing the number of needed screws.

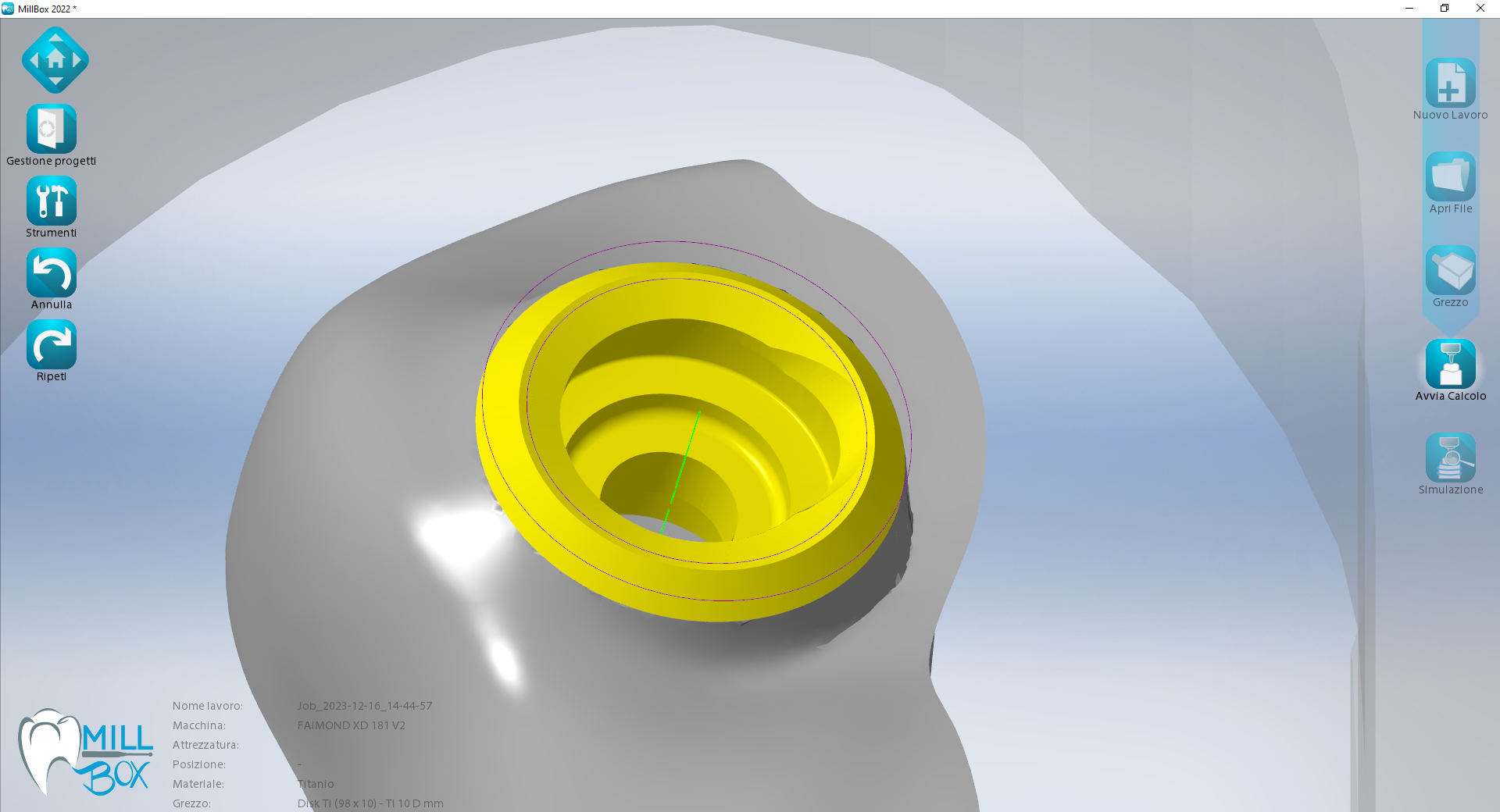

The creation of implant connections can be very complex, especially in cases requiring angled screw channels, and this reduction in the number of needed screws can simplify the work of an operator significantly. Nevertheless, using the OT Bridge system to process cases with extremely high-angled connections is not easy to achieve; requiring specific tools (these vary based on the milling machine type being utilized), a high level of user knowledge and ability to set-up particular processing strategies, and the presence of an innovative and advanced infrastructure that includes software that is up-to-date and is capable of supporting complex processes with reliable, repeatable results.

The OT Bridge protocol is currently being utilized by one of Europe’s most innovative milling centers, CEPROSEM, which is led by Davide Cruciata and located in the south of Italy. This laboratory is equipped with premiere solutions, such as MillBox Dental CAM Software in combination with a Faimond XD 181 milling machine: “The combination of advanced software and reliable CNC machines always plays a key role in dental manufacturing, but is even more important in cases requiring complex processes. What really made the difference for us in operating via OT Bridge was the unique ability to create specific milling strategies for this kind of implant connection, providing a level of tolerance identical to the original, despite having divergences in degrees between the different implants. By applying the OT Bridge protocol it is possible to save up to 25% of screws.”