Yndetech and CIMsystem recently decided to take a new step in dental manufacturing together by integrating laser melting technology with MillBox & Make&Mill dental CAM.

Digitalization of the full dental manufacturing process is the ultimate goal for many working in Digital Dentistry. Digitalization solutions provide results that are reliable, repeatable, and save valuable time and money. Achieving high quality solutions requires collaboration between companies that are innovators in the Digital Dentistry field. That’s why Yndetech and CIMsystem recently decided to take a new step in dental manufacturing together.

Yndetech is a hi-tech Company that provides a full range of dental supplies and assets. They take care of the complete customer journey, offering 3D printers, oral scanners, and design software solutions. Yndetech is also a dental milling center that works with the best-in-class solution providers to produce high quality restorations for patients.

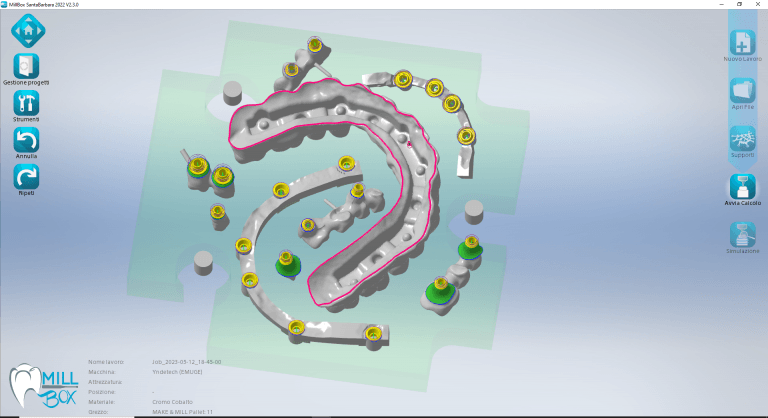

To add additional service value to their customers, Yndetech is utilizing one of CIMsystem’s solutions, Make&Mill, to combine laser melting and milling refining technology in one unique and streamlined workflow. This workflow takes advantage of the time savings afforded by 3D printing while simultaneously producing the high quality that only milling can provide.

“3D printing technology gives operators a certain amount of flexibility with respect to the traditional technique while providing money and saving time. Utilizing 3D printing, operators can be more creative, and can concentrate more on the aesthetic phase of restoration”, says Francesco Grande, CTO of Yndetech.

A closer look at the hybrid solution workflow in dental manufacturing

How do you move from 3D printing a part to refining it on a mill? The process is easy and works seamlessly for Cobalt-chrome overdenture and implant structure restorations. A part/parts are printed on a plate

or with a web on a 3D printer using standard parameters and libraries.

The printed project is placed in the milling machine, the offset is automatically generated, and the project is refined on the mill. The refining phase (milling) is performed by Make&Mill.

Make&Mill is an add on for MillBox, a Dental CAM that is the most popular solution developed by CIMsystem. MillBox offers all the latest available options in cutting edge dental milling technology, with an interface that is intuitive and simplifies the CAM process in the milling workflow. Make&Mill shares these same benefits and is equipped with a brand-new centering system that ensures an even more precise finish!

“CIMsystem is a point of reference in dental manufacturing and MillBox software is the complementary service we were just missing in our lab. The solution hit our expectations thanks to the plating speed, the possibility of adding the offset on the very STL file and the reduced learning curve. Finally, MilBox gives the operator the ability of creating and modifying the milling strategies on his own, which makes the job quicker.” – Francesco Grande, CTO Yndetech.

CIMsystem & Yndetech: a customer centric mission

Both Companies have missions and core values that are united, making for a strong partnership. Yndetech specializes in providing technological innovations and integrations that cover the entire dental manufacturing workflow, while keeping customer needs in mind. The implementation of efficient, affordable, and customized solutions is a key pillar of the partnership between CIMsystem and Yndetech.

“We aim to provide a service of excellence to our customers by investing in innovation while cultivating a positive and transparent attitude. Luckly we can count on strategic partnerships, such as the one we have with CIMsystem, a leader Company in CAD/CAM solutions which contributes daily to our business success and professional growth” (Cit. F. Grande)